Type J Thermocouple Wire - Items tagged as "25ft"

Type J Thermocouple Wire is one of original thermocouple alloy designs and remains in high regard with extensive utilization in plastics, composite. electronics and chemical product development or processing including medical applications. The SLE grade wire can have exceptional accuracy especially in the 212 to 932°F (100 to 500°C) temperature range along with the ability to work well in vacuum or a reducing atmospheres utilized in these industries.

- Type J thermocouple wire is available in Thermocouple grade, Higher accuracy SLE and Extension grade. The thermocouple and SLE grade wire can be utilized to make the actual thermocouple sensors along with ensuring the millivolt signal is maintained at its highest capable accuracy. Extension grade wire is a good choice when extending the signals over longer distances and or where cost can be a key factor.

- Temperature Operating range of 32 to 1400°F (0 to 760°C).

- Wire Sizes can range from fine diameter 40 gage (0.003") to the very large rugged 14 gage diameter (0.064"), although most applications utilize a narrower range of 30 gage (0.010") to 20 gage (0.032")

- Insulations typically include PVC or Fluoropolymers plastics such as FEP, PFA and Polyimide for temperatures from 32 to 600°F, and Fiberglass or Silica glass fiber for temperature above 600 to 1400°F

- Type J bare thermocouple wire consists of the Positive wire made of Iron and the Negative wire made of Constantan (Nickel Copper alloy)

- ANSI (American National Standard Institute) Color Code for Type J Thermocouple wire is White on the positive wire and Red on the Negative Wire.

- The Positive Iron wire in the Type J thermocouple is susceptible to Corrosion and for the sensor to function properly in wet and or corrosive applications the wire should be completely encased or protected by the plastic insulation.

- Industries and Applications who commonly use Type J are automotive testing, heat treating of aluminum, curing composites, vacuum applications and the overall plastics processing

View all

1000ft

100ft

20-awg-pair

20-gage-thermocouple-wire-with-fiberglass-insulation

20-gage-thermocouple-wire-with-pfa-insulation

200ft

200m

24-awg-pair-056-x-093-inch-dia

24-awg-pair-110-max-inch-dia

24-gage-stranded-thermocouple-and-rtd-wire

25ft

30-gage-010-diameter-thermocouple-wire-with-500f-260c-pfa-insulation

30-gage-bare-wire-sensor-010-inch-diameter

30-gage-thermocouple-wire-with-pfa-insulation

500ft

50ft

EXPP-J-24S

FEP-Insulated-Extension-Grade-Thermocouple-Wire

FF-J-24-1000

FF-J-24S-TWSH-1000

fiberglass-insulated-thermocouple-wire-24-gage-solid-900-f-rating

j

j-calibration-tc-wire

pfa-and-aluminum-mylar-inner-shield-on-j-wire

pfa-and-aluminum-mylar-inner-shield-on-k-wire

pfa-plastic-fluoropolymer-on-j-wire

shielded-thermocouples

solid-wire-twisted

thermocouple-extension-wire

thermocouple-wire-with-stainless-steel-braid

TT-J-24-1000

TT-J-30-1000

Twisted-Shielded-Thermocouple-Wire

type-j-thermocouple-extension-wire

type-j-thermocouple-wire

wire-tc-and-rtd

wire-tc-and-rtd-products

-

Type J Thermocouple Wire 24 Gage Solid with PFA Insulation

from $43.00

Type J Thermocouple Wire 24 Gage Solid with PFA Insulation

from $43.00

-

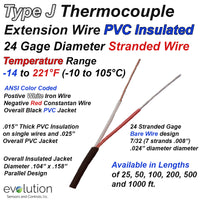

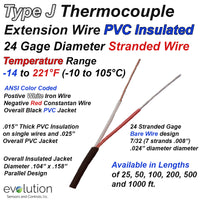

Type J Thermocouple Extension Wire 24 Gage Stranded PVC Insulated

from $36.00

Type J Thermocouple Extension Wire 24 Gage Stranded PVC Insulated

from $36.00

-

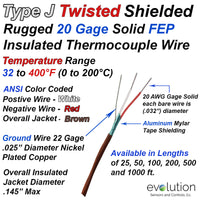

Type J Thermocouple Twisted Shielded Design 24 Gage Solid FEP Insulated

from $64.00

Type J Thermocouple Twisted Shielded Design 24 Gage Solid FEP Insulated

from $64.00

-

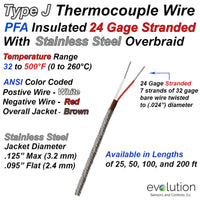

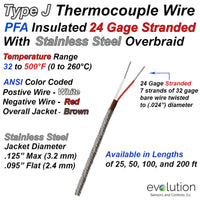

Type J Thermocouple Wire PFA Insulated 24 Gage Stranded with Stainless Steel Overbraid

from $63.00

Type J Thermocouple Wire PFA Insulated 24 Gage Stranded with Stainless Steel Overbraid

from $63.00

-

Type J 24 Gage Stranded Twisted Shielded Thermocouple Wire with FEP Insulation

from $36.00

Type J 24 Gage Stranded Twisted Shielded Thermocouple Wire with FEP Insulation

from $36.00

-

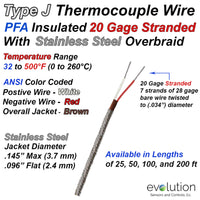

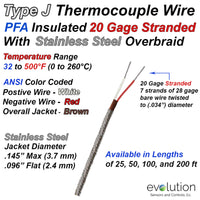

Type J Thermocouple Wire PFA Insulated 20 Gage Stranded with Stainless Steel Overbraid

from $63.00

Type J Thermocouple Wire PFA Insulated 20 Gage Stranded with Stainless Steel Overbraid

from $63.00

-

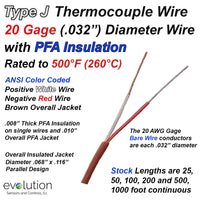

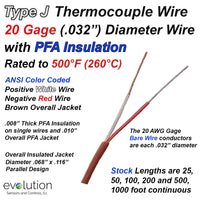

Type J Thermocouple Wire 20 Gage PFA Insulated

from $50.00

Type J Thermocouple Wire 20 Gage PFA Insulated

from $50.00

-

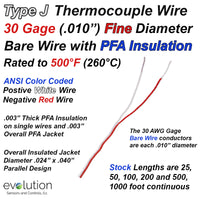

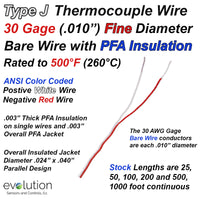

Type J Thermocouple Wire 30 Gage Solid with PFA Insulation

from $54.00

Type J Thermocouple Wire 30 Gage Solid with PFA Insulation

from $54.00

-

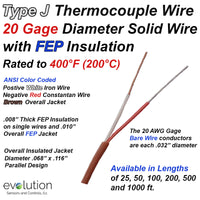

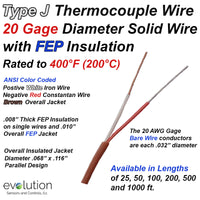

Type J Thermocouple Wire 20 Gage Solid FEP Insulated

from $36.00

Type J Thermocouple Wire 20 Gage Solid FEP Insulated

from $36.00

-

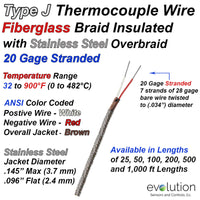

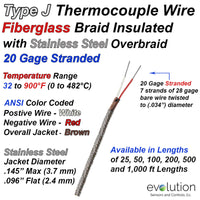

Type J Thermocouple Wire Fiberglass Insulated 20 Gage Stranded with Stainless Steel Overbraid

from $71.00

Type J Thermocouple Wire Fiberglass Insulated 20 Gage Stranded with Stainless Steel Overbraid

from $71.00

-

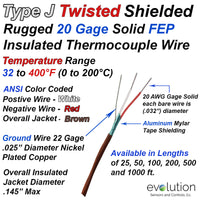

Type J Thermocouple Twisted Shielded Design 20 Gage Solid FEP Insulated

from $128.00

Type J Thermocouple Twisted Shielded Design 20 Gage Solid FEP Insulated

from $128.00

-

Type J Thermocouple Wire Fiberglass Insulated 24 Gage Stranded with Stainless Steel Overbraid

from $64.00

Type J Thermocouple Wire Fiberglass Insulated 24 Gage Stranded with Stainless Steel Overbraid

from $64.00

-

Type J Thermocouple Wire 24 Gage Stranded with FEP Insulation

from $64.00

Type J Thermocouple Wire 24 Gage Stranded with FEP Insulation

from $64.00

-

Type J Thermocouple Wire Fiberglass Braid Insulated 24 Gage Stranded

from $57.00

Type J Thermocouple Wire Fiberglass Braid Insulated 24 Gage Stranded

from $57.00