Surface Temperature Sensors are one the most utilized temperature measurement technologies applied in the Development of New Products, the Refinement of Manufacturing Processes along with providing Reliability Analysis and Predictive Maintenance data on existing products or processes.

This sensor technology is used in an extremely diverse number of applications, such as the surface temperature of a Power Source or CPU for Electronic Control Systems or a Complex Composite Aerospace Parts in an Automated Heat Treating Process or the Motor of a Power Generation System and literally tens of thousands of other applications.

Many times measuring the surface temperature is only one of a few technologies available for to provide critical and insightful data in a Non Destructive and or Extreme Condition Testing without causing additional test variables related to structural and mechanical integrity or contamination of the product.

Like most situations, it comes down to selecting the technology that provides the results and or information required for the desired performance. If Surface Temperature Measurement can provide the solution, your next step is to determine the appropriate sensor technology, such as Thermocouples, RTD's, Infrared Sensors/Cameras and Thermochromic Temperature Labels.

Some of the criteria in selecting the Surface Temperature Sensors will be Accuracy, Reliability, Temperature Range, Response Time, Utilization Diversity, Ruggedness, and Data Content. Other important factors include the ability to touch the object being measured and the cost.

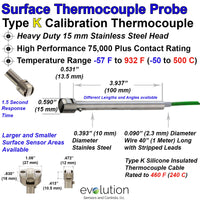

- Surface Thermocouples – well-made thermocouple sensors typically have an accuracy of +/- 2 to 6°F (1 to 3°C) over a wide temperature range. Some temperature drift can occur in certain conditions, although overall the technology is reliable. The response time, diversity and ruggedness is excellent by the inherent nature of this sensor design. The data content is dependent upon the number of thermocouples and instrumentation utilized. The sensor must be in physical contact with the object being measured and they can be an excellent cost to value proposition.

- Resistance Temperature Detectors (RTD's) - the accuracy is excellent. For example, Class A sensors provide an average deviation of +/- 0.5 to 3°F (0.15 -1.5°C) over the sensor temperature range. The technology is extremely reliable, and tests results show less than 0.04% change in resistance over a 5-year period at 400°F (200°C). RTD sensors have a slower response and not quite as diversified or rugged as thermocouples. At the same time RTD's are increasingly being utilized in industrial applications similar to thermocouples. The data content is dependent upon the number of sensors and instrumentation utilized. They also must be in physical contact with the object being measured. Costs have reduced and becoming increasingly price competitive with thermocouples.

- Infrared Thermometers and Cameras - the utilization of this non-contact temperature measurement technology is significantly expanding in the market due to cost reduction with optics, electronics and computing power along with ease of use. The accuracy and range can be similar to thermocouples and is very repeatable. The response time can be very fast, and ability of not contacting the object along with 3 dimensional and adjustable measurements views provides clear advantages in various applications. At the same time, it is electronic based, as such appropriate considerations must be applied in the application environment. The data content far exceeds many other technologies. It is the highest initial cost solution, although in many applications it can be the most capable and provide the best long-term value.

- Thermochromic Temperature Labels - the accuracy of this product technology is excellent with specific temperature ranges. The labels can achieve +/- 2 to 3°F (1 to 1.5°C) in temperature ranges below 212°F to 309°F (100°C to 154°C) and +/- 7°F (4°C) above the 309°F (154°C). A liquid crystal-based design can be as fast as 10 to 100's of milliseconds, and an irreversible design can be as slow as 5 seconds. The labels come in various sizes, and multiple temperature ranges can be achieved with one label. The label construction can be customized to provide diversified solutions. Some designs can provide some increased ruggedness, although they are less capable in this area than Thermocouple and RTD's. The data is very limited in some ways, but at the same time it is unique in the fact irreversible designs provide a permanent data record. The economical pricing, and the fact the labels do not require electrical power to provide a temperature reading, can be the perfect solution for some applications.

If you are in need of additional Surface Temperature Measurement Insight, contact us at info@evosensors.com, visit our website www.evosensors.com or call us at 856 579-7490. We truly enjoy helping the overall technical, scientific and industrial communities with their temperature measurement applications. The EvoSensors team will answer your inquiry quickly and professionally.