Thermocouple Wire - Items tagged as "Expp-k-20-1000"

Thermocouple Wire is the core technology utilized to create the temperature measurement signal with thermocouple probes or sensors. It can also be used to transfer the temperature reading to Instrumentation or to and from a thermocouple connector with the best accuracy results.

Thermocouple Wire is the core technology utilized to create the temperature measurement signal with thermocouple probes or sensors. It can also be used to transfer the temperature reading to Instrumentation or to and from a thermocouple connector with the best accuracy results.

- The 4 Things you should know in selecting the correct thermocouple wire is outlined in the technical specifications below.

- If you already have a Good Working Knowldege of thermocouple wire scroll past the technical details to review individual wire product selections, or utilize the Filter Search tool on the Left of the page.

1. Thermocouple Wire is typically made from 8 Different Types or combinations of thermocouple alloys. It is common for these alloy pairs to be referred as a Calibration or Type and for these wire type pairs to be identified by a letter designation. The correct pairing or matching of the wire alloys is Extremely Important to create and or accurately transfer the temperature measurement signal.

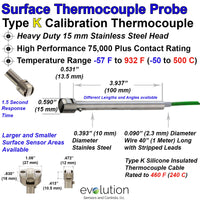

- Type K Thermocouple Wire - is the most commonly utilized design due to its wide termperature range -326 to 2300°F (-200 to 1260°C) CLICK on Each Type Thermocouple Wire for addition details

- Accuracy tolerance below 32°F (0°C) the can exceed the 2.2°C standard limits of error

- Type J Thermocouple Wire - excellent accuracy from 212°F to 932°F (100 to 500°C) the full range tempeature range is 32°F to 1400°F (0 to 750°C)

- Type T Thermocouple Wire - especially accurate and stable in cold to mid level temperatures -380°F to 400°F (–229°C to 200°C)

- Type E Thermocouple Wire - provides the strongest output signal of all thermocouples. Temperature range -454 to 1600°F (-270 to 870°C)

- Type N Thermocouple wire - higher resistance to oxidation and more stability than Type K with a similar wide temperature range 32 to 2300°F (0 to 1260°C

Higher Temperature and or high stabilty thermocouple wire made from Platinum Rhodium or Tungsten Rhenium thermocouple alloys are outlined below, Click on the different Thermocouple Wire types below to view the detailed individual product design

- Type R and S Thermocouple Wire is made from Platinum Rhodium thermocouple alloys designed to be extremely stable and resistant to oxidation with a temperature range up to 2,700°F (1480°C). The extension grade wire is made with with copper and a copper alloy, the wire does NOT contain platinum rhodium materials.

- Type B Thermocouple Wire is also made from Platinum Rhodium thermocouple alloys and provides the highest temperature range for Air and Oxidizing environments with 3,092°F (1700°) temperature on a continuous basis. The extension grade wire made with copper and copper alloy, the wire does NOT contain platinum rhodium materials.

- Type C Thermocouple Wire is made from Tungsten Rhenium alloys and designed for extreme high temperatures up to 4,200°F (2315°C). The thermocouple materials must be utilized in a hydrogen, inert, or vacuum atmospheres to prevent failure from oxidation. The extension grade wire is made from nickel alloys, the wire does NOT contain tungsten rhenium materials.

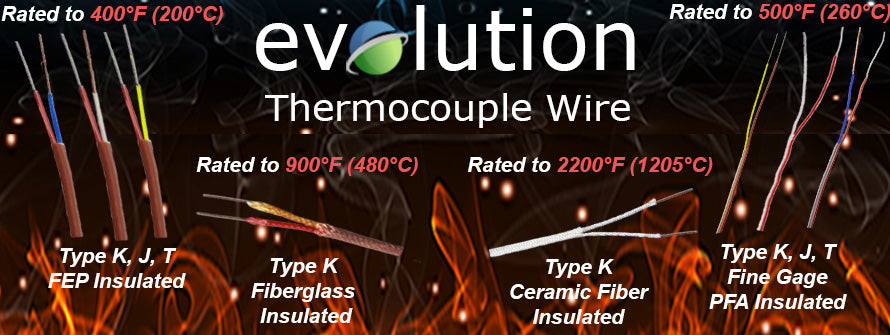

2. Wire Type and the Insulation on the wire pair determine the usable or functional temperature range and capabilities of the thermocouple wire.

- Thermocouple wire can provide a very impressive overall temperature range of - 450°F to 4200°F (-270°C to 2315°C) although it is very important to understand each bare wire pairing and the combination of the insulation applied has its own temperature capabilities along with accuracy capabilities, stability and other characteristics such strength of signal and environmental conditions.

- Insulation on thermocouple wire consists of 3 primary materials classes.

- Thermoplastics such as extruded Teflon's and PVC coatings or polyimide tape for wet, chemical and general abrasion resistant applications from Below Zero to 600°F range.

- Fiber insulation such fiberglass, S2 glass and other Silca based materials or ceramics are used in dry, non abrasive with high temperatures applications up to 2300°F

- Mineral Powder such MgO, Alumina and Hafnia compacted and encased in a metal sheath with the full temperature range of - 450°F to 4200°F (-270°C to 2315°C) and very high level of thermocouple wire protection.

- Metal overbraids, electrical signal interference wraps or shields, along with metal armor and other protection materials can also be applied to the insulated wire

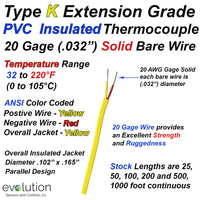

3. Wire Diameters commonly range from the very small diameter .003" (.0762 mm or 40 AWG - American Wire Gage) to a heavy duty rugged diameter of .064" (1.625 mm or 14 AWG) in bare or insulated constructions. Other smaller and larger diameters are available in a limited degree,

- Small Diameters from .003" (40 gage) to .010" (30 gage) provide a fast temperature response and high levels of flexibilty although would not last as long in the higher temperature range of the thermocouple alloy as compared to larger diameters.

- Mid-size and Larger Wire Diameters from .020 (24 gage) to .064 (14 gage) provide the ability to withstand the higher temperture ranges for longer periods of time and allow signal transfer over longer distrances, although have slower temperature response time than the smaller diameters. 24 gage (.020) wire is the most utilized wire diameter.

- The wire inside mineral insulated metal sheath cable is determine by the outside diameter of the metal cable

4. Temperature Accuracy is typically referred to as 3 different grades, classes or levels

-

Special Limits of Error (SLE) - higher level of accuracy, typically plus or minus 2.2°F (1.1°C) accuracy. Type T thermocouple wire can be more accurate in certain temperature ranges. (The international or IEC designation for SLE is Class 1)

-

Standard Grade typically plus or minus 4°F (2.2°C) accuracy. Type T thermocouple wire can be more accurate in certain temperature ranges. (The International term for Standard grade accuracy is Class 2)

- Extension Grade - is primary utilizied to transfer the temperature signal in a temperature environment of 32 to 400°F (0 to 200°C) and should not be used to make a thermocouple