Type J Thermocouples - Items tagged as "24-inches"

Type J Thermocouples have excellent accuracy and stability in the temperature range of 212°F to 932°F (100 to 500°C) and are commonly utilized in the manufacturing, testing, and devlopment in the plastics industry, composites, electronics, inks, coatings and chemicals.

-

Recommended Temperature range is 32°F to 1400°F (0 to 750°C)

- Type J thermocouple alloys have the capability to measure from -346 to 2,192°F (-210 to 1200°C) although this expanded range negatively impacts the linearity (accuracy) sensitivity and the life span-repeatability

-

J Type thermocouples can have Excellent Linearity (stability) in the temperature range of 212°F to 932°F (100 to 500°C) with a deviation of approx. 1.5°F (0.5°C).

- Type J also has the second highest level of sensitivity with a 0.05 to 0.06 millivolt output per degree C.

- The Filter Search tool on the Left or the Clickable product categories below will aid in your selection of the Type J thermocouple products

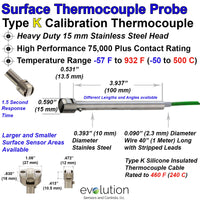

- Type J Thermocouple Probes with a bendable metal stainless steel, Inconel or PFA protected metal sheath for immersion in liquids, gases, air and other industrial applications.

- J Type Beaded Thermocouples designs with fine diameter PFA and Fiberglass insulated lead wire with high flexibility and very fast response time.

- J Type Surface Thermocouples with stick on, and bolt-down versions along with handheld configurations for process equipment monitoring and control

- Type J Thermocouple Connectors include miniature, standard size, panel mounted, circuit board and other configurations available in thermoplastics, thermosets and ceramics.

-

Type J Thermocouple Wire with diameter and insulations from fine diameter 36 gage (.005") to rugged 20 Gage (.032") with Plastic Fluoropolymers to higher temperature Fiberglass and or with Metal Overbraiding.

-

Type J thermocouple alloys consist of Iron for the positive leg (magnetic) and Constantan (Copper Nickel alloy) for the negative leg. (non magnetic)

- The Iron leg is susceptible to oxidation and considerations must be taken especially at higher temperature or utilization of an exposed junction.

-

Color Codes - ANSI, IEC and JIS

- ANSI (American National Standard Institute) White positive, Red negative with Black or Black trace overall with wire and connectors.

- IEC ( International Electrotechnical Commission) Black positive, White negative and Black overall on wire and connectors

- JIS (Japanese Industrial Standard) Red positive, White negative, with Yellow or Yellow trace on wire and connectors

- Industry applications include the overall plastics processing industry including medical products, heat treating of aluminum, curing composites, manufacturing and developing chemicals, paints and other coatings, electronic and materials testing, along with overall research.

View all

0-25-inches-long

032-inch-dia

040-inch-dia

062-inch-dia

1-2-npt-fitting

1-inch-l-x-750-inch-wide

1-inch-long-x-500-inch-wide

1000ft

100ft

118-inch-dia

12-inches

12-inches-long

120-inches

125-inch-dia

144-Inches-12-Ft

18-inches-long

180-inches

188-inch-dia

2-inches-long

20-awg-pair

20-awg-pair-060-x-095-inch-dia

20-gage-beaded-thermocouples-500-f-260-c-pfa-insulation

20-gage-beaded-thermocouples-with-500-f-260-c-pfa-insulation

20-gage-solid-thermocouple-wire-900°F(480°C)-fiberglass-insulation

20-gage-thermocouple-wire-with-fiberglass-insulation

20-gage-thermocouple-wire-with-pfa-insulation

200ft

200m

24-awg-pair-050-x-080-inch-dia

24-awg-pair-056-x-093-inch-dia

24-awg-pair-110-max-inch-dia

24-gage-stranded-thermocouple-and-rtd-wire

24-inches

24-inches-long

240-inches-20ft

250-inch-dia

25ft

3-inches-long

30-awg-pair-037-x-050-inch-dia

30-gage-010-diameter-thermocouple-wire-with-500f-260c-pfa-insulation

30-gage-bare-wire-sensor-010-inch-diameter

30-gage-thermocouple-wire-with-pfa-insulation

30-inches-long

36-awg-pair-019-x-030-inch-dia

36-gage-005-pfa-insulated-thermocouple-beads

4-inches-long

40-inches

48-inches

5-inches-long

500ft

50ft

5srtc-gg-j-30-36

5srtc-gg-j-30-72

5srtc-tt-j-30-72

5tc-gg-j-20-36

5tc-gg-j-20-72

5tc-gg-j-24-72

5tc-gg-j-30-40

5tc-gg-j-30-72

5tc-tt-j-20-36

5tc-tt-j-24-36

5tc-tt-j-24-72

5tc-tt-j-30-36

5tc-tt-j-30-72

5tc-tt-j-36-36

5tc-tt-j-36-72

6-inches-long

60-inches

72-inches

8-inches-long

80-inches

96-inches

beaded-wire-sensor

beaded-wire-thermocouples-with-miniature-connectors

connector-extension-cable-mini-male-female

connectors-and-fittings

dual-thermocouple-probe-with-standard-size-connectors

exposed

EXPP-J-24S

FEP-Insulated-Extension-Grade-Thermocouple-Wire

FF-J-24-1000

FF-J-24S-TWSH-1000

fiberglass-ins-wire

fiberglass-insulated-thermocouple-wire-24-gage-solid-900-f-rating

flat-pin

flat-weld-bead

grounded

handheld-thermocouple-probes

ICSS-116G-12-PFA

ICSS-116G-18-PFA

ICSS-18G-12-PFA

ICSS-18G-18-PFA

inconel-600

j

j-calibration-tc-wire

j-fast-response

JMQSS-062G-3

JMQSS-062G-6

JMQSS-062U-6

JMQSS-125G-3

JMQSS-125G-4

JMQSS-125U-6

JQIN-18U-12

JQSS-18G-12

JQSS-18G-18

JQSS-18G-3

JQSS-18U-6

JQSS-316U-12

LJ-J

metal-transition-to-lead-wire

Mini Plastic Co

Mini Plastic Conn

mini-male-plastic-connector

mini-plastic-connector

miniature-ceramic-female

miniature-ceramic-male

miniature-duplex-female

miniature-duplex-male

miniature-female

miniature-female-thermocouple-connectors-400-f-200-c-rated

miniature-high-temperature-female

miniature-high-temperature-male

miniature-locking-female

miniature-locking-male

miniature-male

miniature-male-plastic-connector

miniature-male-thermocouple-connectors-400-f-200-c-rated

miniature-panel-jack

miniature-panel-mount

miniature-pcb-flat-mounting

miniature-thermocouple-connectors

miniature-three-pin-female

miniature-three-pin-male

MPJ-J-F

OST-J-M-ROHS

OSTW-J-F

OSTW-J-F-ROHS

OSTW-J-M

OSTW-J-M-ROHS

pcb-thermocouple-connectors

pfa-and-aluminum-mylar-inner-shield-on-j-wire

pfa-and-aluminum-mylar-inner-shield-on-k-wire

pfa-coated-thermocouple-probe

pfa-coated-thermocouple-probe-with-miniature-flat-pin-male-connector

pfa-coated-thermocouple-probes

pfa-plastic-fluoropolymer-on-j-wire

plastic-fluoropolymer-ins-wire

plastic-fluoropolymer-ins-wire-ss-braid

plastic-fluoropolymer-insulated-wire

polyimide-glass-reinforced-tape

round-pin

rtd-probes-with-fittings

SA1-J

SA1-J-120-SC

SA1-J-120-SRTC

SA1-J-72

SA1-J-72-SC

SA1-J-72-SRTC

SA1-J-SRTC

SA1-Self Adhesive Patch 1 Inch

SA1XL - Self Adhesive 1 inch Patch Xtra Line

SA1XL-J

SA1XL-J-120

SA1XL-J-120-SRTC

SA1XL-J-72

SAS-TRJE-4-36

self-adhesive-patch-with-wire-and-connector

self-adhesive-patch-with-wire-leads

shielded-thermocouples

SHX-J-F

SHX-J-M

SMPW-J-F

SMPW-J-M

solid-wire-twisted

SPJ-J-F

stainless-steel-304

stainless-steel-316

standard-ceramic-female

standard-ceramic-male-hollow-pins

standard-ceramic-male-solid-pins

standard-duplex-female

standard-duplex-male

standard-female

standard-high-temperature-female

standard-high-temperature-male

standard-male

standard-male-dual-connector

standard-male-hi-temp-plastic-connector

standard-male-plastic-connector

standard-panel-insert-flanged

standard-panel-jack

standard-thermocouple-connectors

standard-three-pin-female

standard-three-pin-male

stripped-ends

stripped-wire-leads

surface-thermocouple-probes

surface-thermocouple-with-non-adhesive-patch

surface-thermocouples-bolt-on-design

TAS-J-2

TAS-J-3

tc-connectors

tc-mi-cable-probe

tc-surface-probe

TECJ10-13

thermocouple

thermocouple extension cable with female connector and stripped leads

thermocouple-adapters

thermocouple-and-rtd-sensors-with-stripped-wire-ends

thermocouple-connector

thermocouple-extension-cable-with-miniature-male-connector

thermocouple-extension-cables

thermocouple-extension-cables-and-connector-assemblies-with-stripped-ends

thermocouple-extension-wire

thermocouple-panel-jacks

thermocouple-probes

thermocouple-probes-with-900°F-fiberglass-rated-leads

thermocouple-probes-with-lead-wire-and-miniature-plastic-connector

thermocouple-probes-with-miniature-connectors

thermocouple-wire-with-stainless-steel-braid

Thermocouples-with-20-Gage-Fiberglass-Insulated-Leads

THMJ-SJ

threaded-probe

threaded-thermocouple

TJ240-ICSS-14U-12-SB

TJ36-ICSS-116U-6-SB

TJ36-ICSS-116U-6-SB-SMPW-M

TJ36-ICSS-14U-12

TJ36-ICSS-14U-12-SB

TJ36-ICSS-14U-6

TJ36-ICSS-14U-6-SMPW-M

TJ36-ICSS-316E-4

TT-J-24-1000

TT-J-30-1000

Twisted-Shielded-Thermocouple-Wire

type-j-dual-thermocouple

type-j-thermocouple-extension-wire

type-j-thermocouple-wire

ungrounded

wire-bead-weld

wire-tc-and-rtd

wire-tc-and-rtd-products

WTJ-HD-72-S